Why on earth did the Mercedes engineers use weak plastic connectors (marked A and B in the images below) in the C180 Kompressor model W205 engine coolant expansion system?

These two weak points tend to break, and break again - and Mercedes has the temerity to charge and arm and a leg to replace them.

The cost of the field replaceable unit (image 1) is approximately AUD $150 to $160.

It's crazy that the broken connector (marked A in image 2 below) cannot be purchased separately for a few dollars!

I used copper tubing to rebuild connector A …

Image 5 below shows the finished repair:

Just when I thought that I had finished the repair, to my great annoyance the plastic connector on the coolant expansion tank snapped off. It was too weak to withstand the stress of reattaching the rubber connecting tube at point B.

You can assess just how exposed to being broken it is from image 6 below. When this fragile connector (B) breaks off the entire tank becomes useless, and your vehicle is rendered effectively undriveable.

So it looks like I'll have to try using copper tubing to rebuild the pipe on the coolant expansion tank. Otherwise a replacement tank will be needed, at a cost of around AUD $100, and that's inexcusable.

Obviously not all Mercedes Benz engineering design and implementation features reach the exalted heights often associated with the Mercedes name. So-called "German engineering excellence" – Phooey!

Examine just about any product of any sort (and that certainly includes software), developed by any organisation anywhere in the world, and you’ll find weak points without having to look too hard.

UPDATE (26 July 2018)

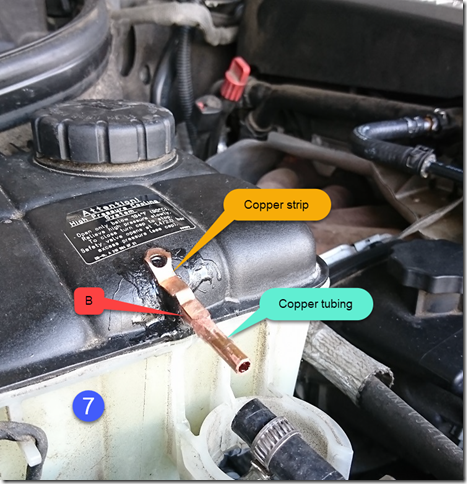

Yesterday I filed the end of a 3 or 4 cm length of copper tubing so that it was a snug fit into the hole left at the top of the coolant expansion tank. I also prepared a small copper strip to sit on top of the tubing and used epoxy resin (Selleys Araldite brand, here in Australia) to glue the tubing and strip in place. Then, it being cool winter weather in Melbourne, I waited a day to allow the epoxy resin to set firm.

Here’s what my latest burst of jury rigging accomplished (image 7):

Today I gingerly tested the strength of the bond, and it seems to be pretty strong, I would say at least as strong as the stupid original plastic tube shown in image “6”.

The only thing left to do is to start driving again and keep a watchful eye out for the “Check coolant level” warning, hoping never to see it again. Only time will tell.

By the way, I highly recommend Solvol heavy-duty hand cleaner for washing your hands after work such as this. It comes in a convenient bottle as shown below:

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.